12

ENGINE

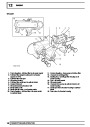

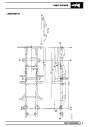

Connecting rods

1.

2.

Small-end oil holes

Small-end bushing

3. Connecting rod

4. Serrated fracture

The connecting rods are machined, H-section steel forgings which feature a fracture-split at the big-end between

the connecting rod and the bearing cap. The connecting rod features a serrated fracture across the big-end at

right angles to the length of the connecting rod, this forms a unique mating surface between the connecting rod

and the fractured end which is used as the big-end cap. The use of a fracture split in the big-end of the connecting

rod ensures a perfect match for assembly on the crankshaft bearing journals and provides the connecting rod with

strong resistance to lateral movement.

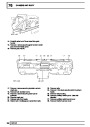

The end-cap fixing bolts are offset to ensure that the cap is fitted to the connecting rod in the correct orientation. If

the end-cap is fitted incorrectly and the end-cap bolts tightened, the connecting rod must be replaced, since the

matching serrations will have been damaged.

The big-end bearing shells are plain split halves without location tags. On EU2 vehicles the two halves of the

bearing shells are of different construction. The upper half bearing shell fitted to the connecting rod is treated

using the sputtering process to improve its resistance to wear. The connecting rod bearing shell can be identified

by having a slighter darker colouration than the big-end bearing cap shell, and the back face of the connecting rod

bearing shell has a shinier finish than the front face.

On EU3 vehicles both bearing shells are of the same construction as the connecting rod bearing shell.

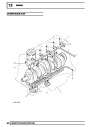

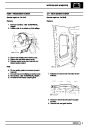

The small-end of the connecting rod has a bushed solid eye which is free to move on the gudgeon pin, the

bushing is a hand push, interference fit. The steel bushing has two slots machined in its upper surface for

providing oil lubrication to the moving surface of the gudgeon pin. The oil slots must be correctly aligned to the oil

slots provided in the small end of the connecting rod. The small-end lubrication is supplied by squirt feed from the

piston lubrication jets.

14

DESCRIPTION AND OPERATION

Product Specification

| Categories | Land Rover, Land Rover Defender |

|---|---|

| Tags | Land Rover |

| Model Year | 1999, 2000, 2001, 2002 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Defender |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |