224

MAINTAININGYOURVEHICLE

•

•

Checkcoolantfreezepointinthesystem.

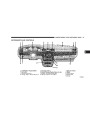

HosesandVacuum/VaporHarnesses

Inspectsurfacesofhosesandnylontubingforevidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tears, cuts, abrasions,

andexcessiveswellingindicatedeteriorationoftherub-

ber.

If frequent coolant additions are required, or if the

levelinthebottledoesnotdropwhentheenginecools,

thecoolingsystemshouldbepressuretestedforleaks.

•

Maintaincoolantconcentrationat50%HOATethylene

glycol engine coolant (minimum) and distilled water

forpropercorrosionprotectionofyourenginewhich

containsaluminumcomponents.

Pay particular attention to those hoses nearest to high

heatsourcessuchastheexhaustmanifold.Inspecthose

routingtobesurehosesdonottouchanyheatsourceor

moving component that may cause heat damage or

mechanicalwear.

•

•

Make sure that the radiator and coolant bottle hoses

arenotkinkedorobstructed.

Keepthefrontoftheradiatorclean.Ifyourvehiclehas

airconditioning,keepthefrontofthecondenserclean,

also.

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

andcouplingstomakesuretheyaresecureandnoleaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

causefailure.

•

Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLYthecorrecttypethermostat.Otherdesignsmay

resultinunsatisfactorycoolingperformance,poorgas

mileage,andincreasedemissions.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggestedserviceintervalscanbefoundinsection8.

Product Specification

| Categories | Chrysler Manuals, Chrysler Sebring Manuals |

|---|---|

| Model Year | 2005 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |