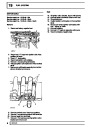

CHASSIS AND BODY

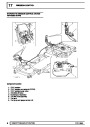

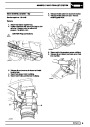

Refit

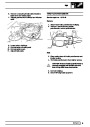

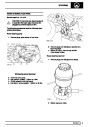

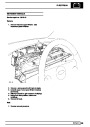

WINDSCREEN GLASS

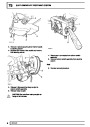

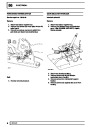

CAUTION: When refitting avoid trapping

electrical wiring.

Service repair no - 76.81.01

Information

29.

30.

Reverse removal procedure.

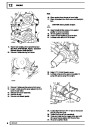

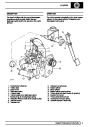

With assistance: Position dash panel and

connect dash harness multiplugs to fusebox and

main harness.

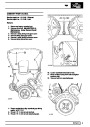

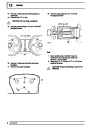

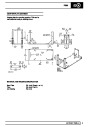

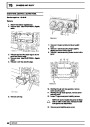

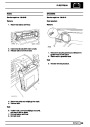

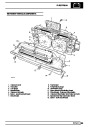

The following equipment is required:

• Cutting wire and handles

31.

32.

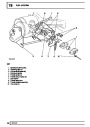

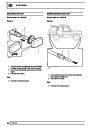

Reverse removal procedure. Ensure dash panel

upper bracket studs are located before the 4

lower brackets.

Reverse removal procedure. Disconnect

glovebox switch Lucars to ease fitting of relay

bracket.

• Windscreen repair kit (see Technical

Bulletin). See Electrical Trouble Shooting

Manual.Windscreen Glass Replacement.

• Sealant applicator gun.

•

Suction cup lifters.

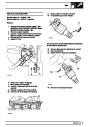

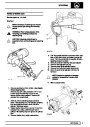

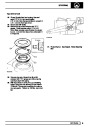

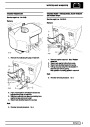

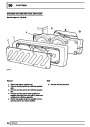

The following materials are included in the windscreen

repair kit:

•

Glass cleaning solvent - ’Betawipe’ Glass

activator (yellow cap).

•

•

•

Cotton buds.

Glass primer - ’Betaprime’(green cap).

Body primer - ’Betaprime’ paint/plastic

primer (red cap).

•

Betaseal Adhesive sealant.

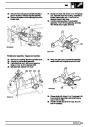

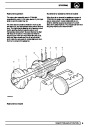

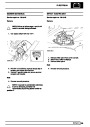

NOTE: The adhesive sealant cures in 6 to 8

hours

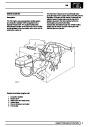

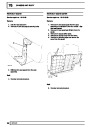

CAUTION: Once existing sealant is cut, the

exposed surfaces oxidises in

approximately 90 minutes. The refit

procedure must be completed within this time

span to prevent the sealant oxidising, to effect a

satisfactory joint.

CAUTION: If the windscreen aperture body

flange shows signs of corrosion it must be

treated with anti corrosion primer and

repainted. Newly painted areas must then be left

for 8 hours or more before applying adhesive

sealant.

REPAIR

49

Product Specification

| Categories | Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1998 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |