82

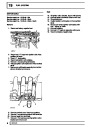

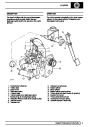

AIR CONDITIONING

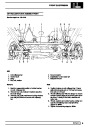

SERVICING PRECAUTIONS

A new compressor is sealed and pressurised with

Nitrogen gas, slowly release the sealing cap, gas

pressure should be heard to release as the seal is

broken.

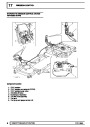

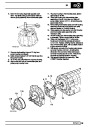

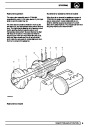

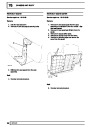

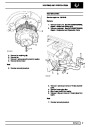

Care must be taken when handling refrigeration

system components. Units must not be lifted by their

hoses, pipes or capillary lines. Hoses and lines must

not be subjected to any twist or stress. Ensure that

hoses are positioned in their correct run before fully

tightening the couplings, and ensure that all clips and

supports are used. Torque wrenches of the correct

type must be used when tightening refrigerant

connections to the stated value. An additional wrench

must be used to hold the union to prevent twisting of

the pipe.

NOTE: A new compressor should always

have its sealing caps in place and must

not be removed until immediately prior to

fitting

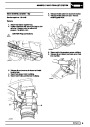

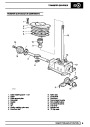

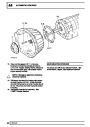

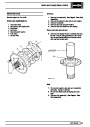

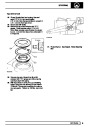

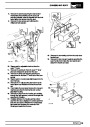

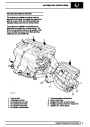

Fitting a new compressor

A new compressor is supplied with an oil fill (X) of:

180ml

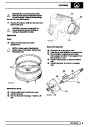

Before connecting any hose or pipe ensure that

refrigerant oil is applied to the seat of the new ’0’ ring

but not to the threads.

A calculated quantity of oil must be drained from a

new compressor before fitting.

To calculate the quantity of oil to be drained:

Check the oil trap for the amount of oil lost.

All protective plugs on components must be left in

place until immediately prior to connection.

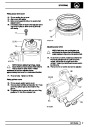

The receiver/drier contains desiccant which absorbs

moisture. It must be positively sealed at all times.

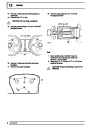

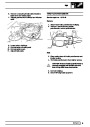

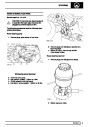

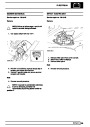

1. Remove sealing plugs from the OLD compressor

2. Invert compressor and gravity drain oil into

measuring cylinder. Rotating the compressor

clutch plate will assist complete draining.

3.

Note the quantity of oil drained (Y).

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

4. Calculate the quantity (Q) of oil to be drained

from the NEW compressor using the following

formula:

X - (Y + 20ml) = Q

Use alcohol and a clean cloth to clean dirty

connections.

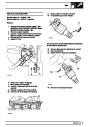

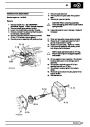

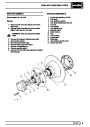

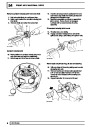

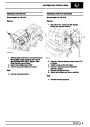

Rapid refrigerant discharge

Ensure that all new parts fitted are marked for use

with R134a.

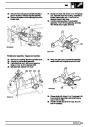

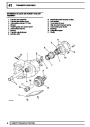

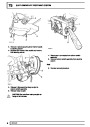

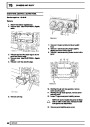

When the air conditioning system is involved in

accident damage and the circuit is punctured, the

refrigerant is discharged rapidly. The rapid discharged

of refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled as follows:

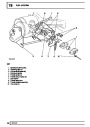

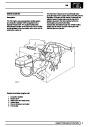

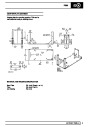

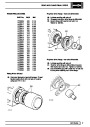

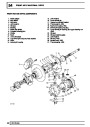

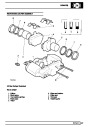

Refrigerant oil

Use the approved refrigerant lubricating oil:

Nippon Denso ND-OIL 8

Unipart R134a ND-OIL8

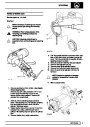

1.

Gravity drain all the oil, assist by rotating the

clutch plate (not the pulley).

CAUTION: Do not use any other type of

refrigerant oil.

2. Refill the compressor with the following amount

of new refrigerant oil:

Refrigerant oil easily absorbs water and must not be

stored for long periods. Do not pour unused oil back

into the container.

130ml

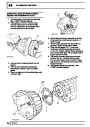

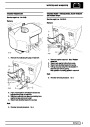

When renewing system components, add the

following quantities of refrigerant oil:

3. Plug the inlet and outlet ports.

Condenser .......................................................... 40ml

Evaporator .......................................................... 80ml

Pipe or hose ........................................................ 20ml

Receiver/drier...................................................... 20ml

Total of refrigerant oil in system = 180ml = 6.3 Fl

oz

2

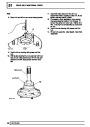

ADJUSTMENT

Product Specification

| Categories | Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1998 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |