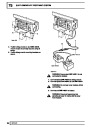

AIR CONDITIONING

AIR CONDITIONING SYSTEM OPERATION

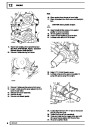

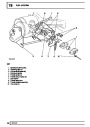

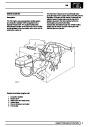

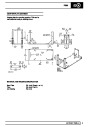

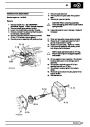

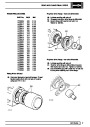

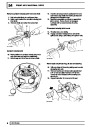

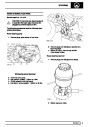

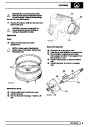

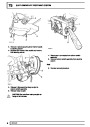

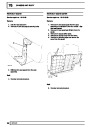

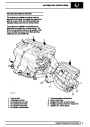

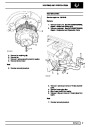

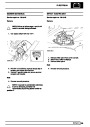

Should the temperature at the evaporator (5) fall low

enough for ice to begin to form on the fins, the

thermostat disengages the clutch and also isolates the

cooling fans relays. When the temperature at the

evaporator (5) rises to the control temperature, the

clutch is re-engaged.

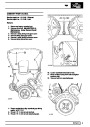

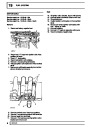

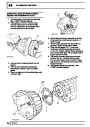

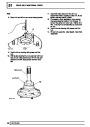

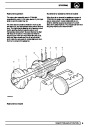

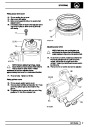

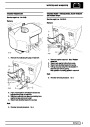

The air conditioning system provides the means of

supplying cooled and dehumidified, fresh or

recirculated air to the interior of the vehicle. The

cooling effect is obtained by blowing air through the

matrix of an evaporator unit and when required,

mixing that air with heated air by means of the heater

distribution and blend unit, to provide the conditions

required inside the vehicle. The volume of conditioned

air being supplied is controlled by a variable speed

blower.

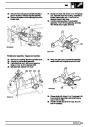

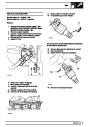

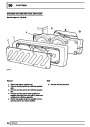

Should the system pressure become excessive or

drop sufficiently to cause damage to the compressor

(1) a dual pressure switch (7), located in the high

pressure line, signals the relay unit to disengage the

clutch. The compressor also has an emergency high

pressure relief valve (9) fitted.

A sealed system, charged with Refrigerant R134a,

together with a blower unit, blend unit and control

system combine to achieve the cooled air condition.

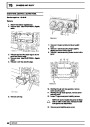

The cooling fans are controlled by engine temperature

when the air conditioning is not switched on.

For air conditioning air distribution system. See

HEATING AND VENTILATION, Description and

operation, Heating and ventilation unit

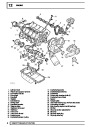

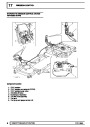

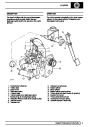

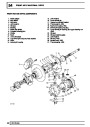

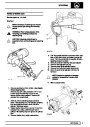

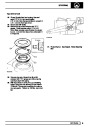

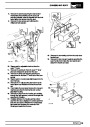

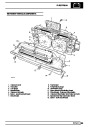

2. Condenser

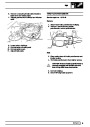

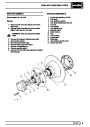

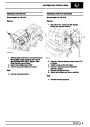

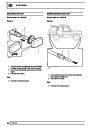

From the compressor, hot high pressure vaporised

refrigerant (F1) passes to the condenser (2), which is

mounted in front of the engine coolant radiator. Ram

air(A1) passing through the condenser (2),

supplemented by 2 cooling fans (8) mounted in front

of the condenser, cools the refrigerant vapour

sufficiently to form a high pressure slightly subcooled

liquid (F2).

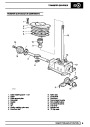

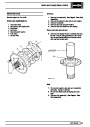

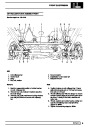

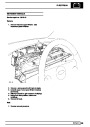

The air conditioning system comprises five major

units:

1.

2.

3.

An engine-mounted compressor.

A condenser mounted in front of the radiator.

A receiver/drier unit located in front of the

condenser.

4.

5.

Thermostatic expansion valve mounted above

the evaporator.

An evaporator unit mounted in front of the heater

matrix.

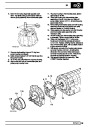

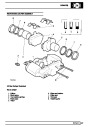

3. Receiver/drier

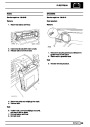

This liquid then passes to a receiver/drier (3) which

fulfils two functions. It acts as a reservoir and moisture

extractor (11).

NOTE: Vehicles fitted with rear air

conditioning have an additional

evaporator/blower motor assembly located

A sight glass (10), in the high pressure line, provides a

method of determining the state of the refrigerant

without breaking into the system.

behind the LH rear compartment lower trim panel.

These units are interconnected by hoses and pipes

carrying Refrigerant R134a, the evaporator is linked

into the vehicle ventilation system.

4. Expansion valve

From the receiver/drier (3) the moisture free high

pressure liquid refrigerant (F3) passes through a

thermostatic expansion valve (4). A severe pressure

drop occurs across the valve and as the refrigerant

enters the evaporator space at a temperature of

approximately -5°C it boils and vaporises.

Refrigeration cycle

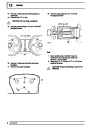

1.

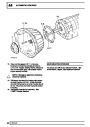

Compressor

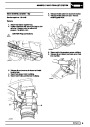

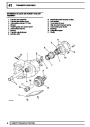

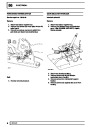

The compressor (1), belt driven from the crankshaft

pulley, pressurises and circulates the refrigerant

through the system. Mounted on the compressor, an

electro-mechanical clutch maintains the correct

temperature and pressure by engaging or disengaging

to support the system’s requirements. The clutch

action is normally controlled by a thermostat located

at the evaporator (5). The compressor is of the

swashplate type having fixed displacement.

DESCRIPTION AND OPERATION

3

Product Specification

| Categories | Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1998 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |