EMISSION CONTROL

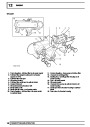

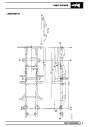

EGR System - Type 2

This system features twin modulators mounted one above the other on a metal plate located on the inner wing at

the RH side of the engine. The modulators are electrically controlled by the engine management system and are

used to modulate a vacuum source to the EGR valve and a supplementary Inlet Throttle (ILT) valve; the two

valves are controlled to operate in tandem. The ILT valve vacuum pot is mounted adjacent to the EGR valve

housing and has a linkage which connects to a butterfly valve mounted in front of the EGR valve at the air intake

manifold.

The modulator operations are electrically controlled by signals from the engine management system which

determines the required volume of exhaust gas needed in response to inputs relating to air flow, engine operating

conditions and ambient parameters such as temperature and altitude. The engine management ECM switches on

the circuit by completing the path to ground, operating the vacuum modulators.

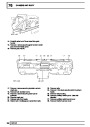

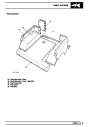

Pre EU3 models: The exhaust gases are routed from the exhaust manifold through a shaped metal pipe which

connects to the underside of the EGR valve. The pipe is held securely in position to the front of the engine cylinder

head using a metal clamp bracket. The EGR pipe is attached to a mating port at the front end of the exhaust

manifold using two Allen screws and at the EGR valve assembly by a metal band clamp. The two Allen screws

fixing the EGR pipe to the exhaust manifold should be replaced every time the EGR pipe is removed.

CAUTION: Extreme care should be exercised when removing and refitting the EGR pipe to avoid

damage.

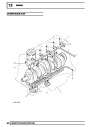

EU3 models: The exhaust gases are routed from the exhaust manifold through the EGR cooler to the underside

of the EGR valve. The EGR cooler is bolted to the front of the engine cylinder head. An EGR pipe connects the

EGR cooler to the exhaust manifold and is secured by two Allen screws. The two Allen screws fixing the EGR pipe

to the exhaust manifold should be replaced every time the EGR pipe is removed. A second pipe connects the

EGR cooler to the EGR valve; this pipe is secured to the EGR valve by a clip, and to the cooler by two Allen

screws.

CAUTION: Extreme care should be exercised when removing and refitting the EGR pipe to avoid

damage. When refitting the EGR cooler, always tighten the pipe connections BEFORE tightening

the bolts securing the cooler to the cylinder head.

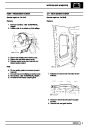

When a vacuum is applied to the EGR suction port, it causes a spindle with sealing disc (EGR valve) to be raised,

opening the port at the EGR pipe to allow the recirculated exhaust gas to pass through into the inlet manifold. The

valve is spring loaded so that when the vacuum is removed from the suction port, the valve returns to its rest

position to tightly close the exhaust gas port.

A vacuum is simultaneously applied to the inlet throttle (ILT) valve suction port which causes the butterfly valve in

the inlet manifold to close by means of a spindle and lever mechanism. Closing the butterfly valve limits the supply

of fresh intercooled air entering the inlet manifold and causes a depression within the inlet manifold to create a

greater suction at the open port to the EGR delivery pipe. In this condition a greater mass of recirculated exhaust

gas is drawn into the inlet manifold for use in the combustion process. When the vacuum is released from the ILT

valve suction port a spring returns the butterfly valve to its fully open position.

By controlling the quantities of recirculated exhaust gas and fresh intake air available in the inlet manifold, the

optimum mix for the prevailing engine operating conditions can be maintained which ensures the intake gas to the

combustion chambers will have burning rate properties which will reduce the NO2 emissions to an acceptable

level. Normally, full recirculation is only applicable when the NO2 emissions are most prevalent.

DESCRIPTION AND OPERATION

15

Product Specification

| Categories | Land Rover, Land Rover Defender |

|---|---|

| Tags | Land Rover |

| Model Year | 1999, 2000, 2001, 2002 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Defender |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |