PANEL REPAIRS

Stone Chip Resistant Paint/Primer

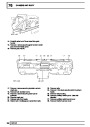

Re-treat all areas protected with factory-applied

anti-chip primer with suitable approved material in

repair.

NOTE: The presence of small blisters in

PVC underbody sealer is acceptable,

providing they do not expose bare metal.

Special attention must be paid to signs of damage

caused to panels or corrosion material by incorrect

jack positioning.

Inspections during Maintenance Servicing

It is a requirement of the Land Rover Corrosion

Warranty that the vehicle body is checked for

corrosion by an authorised Land Rover dealer at least

once a year, to ensure that the factory-applied

protection remains effective.

It is essential to follow the correct jacking and lifting

procedures. See GENERAL INFORMATION DATA,

Information section.

Service Job Sheets include the following operations to

check bodywork for corrosion:

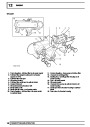

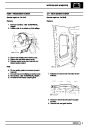

With the vehicle lowered, visually check for evidence

of damage and corrosion on all painted areas, in

particular the following:

•

•

With the vehicle on a lift, carry out visual

check of underbody sealer for damage.

•

•

Front edge of bonnet.

With the vehicle lowered, inspect exterior

paintwork for damage and body panels for

corrosion.

Visible flanges in engine compartment and

boot.

•

Lower body and door panels.

NOTE: Wash the vehicle and ensure that it

is free from deposits prior to inspection. It

is part of the owner’s responsibility to

ensure that the vehicle is kept free of

accumulations of mud which could accelerate the

onset of corrosion. The Dealer MUST wash the

vehicle prior to inspection of bodywork if the

customer has offered it in a dirty condition, and

pay special attention to areas where access is

difficult.

Where bodywork damage or evidence of corrosion is

found during inspection, rectify this as soon as is

practicable, both to minimise the extent of the damage

and to ensure the long term effectiveness of the

factory-applied corrosion protection treatment. Where

the cost of rectification work is the owner’s

responsibility, the Dealer must advise the owner and

endorse the relevant documentation accordingly.

Where corrosion has become evident and is

NOTE: The checks described above are

intended to be visual only. It is not

intended that the operator should remove

trim panels, finishers, rubbing strips or sound

deadening materials when checking the vehicle

for corrosion and paint damage.

emanating from beneath a removable component

(e.g. trim panel, window glass, seat etc.), remove the

component as required to permit effective rectification.

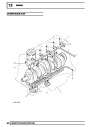

With the vehicle on a lift, and using an inspection or

spot lamp, visually check for the following:

•

Corrosion damage and damaged

paintwork, condition of underbody sealer

on front and rear lower panels, sills and

wheel arches.

•

Damage to underbody sealer on main floor

and chassis members. Corrosion in areas

adjacent to suspension mountings and fuel

tank fixings.

SEALING AND CORROSION PROTECTION

9

Product Specification

| Categories | Land Rover, Land Rover Defender |

|---|---|

| Tags | Land Rover |

| Model Year | 1999, 2000, 2001, 2002 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Defender |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |