PANEL REPAIRS

BODY REPAIRS

Where major units have been disconnected or

removed, it is necessary to ensure that fluid levels are

checked and topped up when necessary. It is also

necessary to ensure that the repaired vehicle is in a

roadworthy condition in respect of tyre pressures,

lights, washer fluid etc.

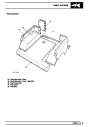

Body shells are of riveted, bolted and welded

construction and are bolted to the chassis frame.

It is essential that design dimensions and strength are

restored in accident rectification. It is important that

neither structural weakness nor excessive local

stiffness are introduced into the vehicle during body or

chassis repair.

Body repairs often involve the removal of mechanical

and electrical units as well as associated wiring.

Where this is necessary use the relevant section in

this manual.

Repairs usually involve a combination of operations

ranging from straightening procedures to renewal of

either individual panels or panel assemblies. The

repairer will determine the repair method and this

decision will take into account a balance of economics

between labour and material costs and the availability

of repair facilities in both equipment and skills. It may

also involve considerations of vehicles down-time,

replacement vehicle availability and repair turn-around

time.

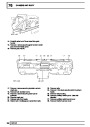

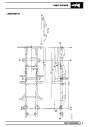

Taking into consideration the differences in body

styles, steering and suspension systems as well as

engine and suspension layouts, the location of the

following components as applicable to a particular

vehicle is critical:

•

Front suspension upper damper

mountings.

•

•

Front suspension or sub frame mountings.

It is expected that a repairer will select the best and

most economic repair method possible, making use of

the facilities available. The instructions given are

intended to assist a skilled body repairer by expanding

approved procedures for panel replacement with the

objective of restoring the vehicle to a safe running

condition and effecting a repair which is visually

acceptable and which, even to the experienced eye,

does not advertise the fact that it has been damaged.

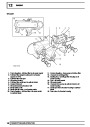

Engine mountings on RH and LH chassis

longitudinals.

•

•

Rear suspension upper damper mountings.

Rear suspension mountings or lower

pivots.

•

Steering rack mountings.

This does not necessarily mean that the repaired

vehicle will be identical in all respects with original

factory build. Repair facilities cannot always duplicate

methods of construction used during production.

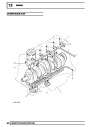

Additional points which can be used to check

alignment and assembly are:

•

Inner holes in crossmember - side - main

floor.

The panel repairs shown in this section are all based

on a 110 Station Wagon. Therefore all illustrations

and text relate only to this model. Although certain

areas of the vehicle, such as the front end, are

relevant to all models.

•

•

•

•

Holes in valance front assembly.

Body to chassis mounting holes.

Holes in rear floor.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and suspension

geometry checked after completion and if necessary a

road test of the vehicle is carried out, particularly

where safety related items are concerned.

Holes in rear lower panels or extension

rear floor.

•

Fuel tank mountings.

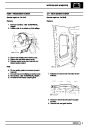

Apertures for windscreen, backlight, bonnet and doors

can be checked by offering up an undamaged

component as a gauge and also by measuring known

dimensions. See BODY DIMENSIONS section.

INFORMATION

1

Product Specification

| Categories | Land Rover, Land Rover Defender |

|---|---|

| Tags | Land Rover |

| Model Year | 1999, 2000, 2001, 2002 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Defender |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |