77

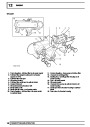

PANEL REPAIRS

CORROSION PROTECTION

NOTE: Application of new underbody

sealer must be carried out between primer

and surfacer paint operations. Areas

where seam sealer is used should be re-treated as

necessary before application of underbody sealer.

The following information details the materials that are

applied during manufacture for corrosion protection.

Factory Treatments

The Defender is treated with the following

anti-corrosion materials in production:

CAUTION: Ensure that suspension units,

wheels, tyres, power unit, driveshafts,

exhaust and brakes (including all

•

•

•

A PVC-based underbody sealer material

which is sprayed onto the underfloor, wheel

arches and undersill areas.

mounting points) are shielded prior to application

of fresh underbody sealer.

Cavity Wax

An application of cavity wax which is

sprayed into enclosed cavities and box

sections.

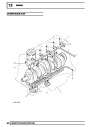

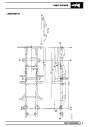

Cavity wax is applied to certain box sctions The

information given on the following pages is intended

as a guide and shows the areas to be treated with

cavity wax, as well as the access holes used during

manufacture. See GENERAL INFORMATION DATA,

Sealing and corrosion protection section.

A final coating of underbody wax to cover

the complete underfloor including

components but excluding brake discs,

exhaust system and propeller shafts.

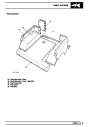

Underbody Wax

A coat of underbody wax is applied to the entire

underbody inboard of the sill vertical flanges, and

covers all moving and flexible components EXCEPT

for wheels and tyres, brakes and exhaust. The wax is

applied over paints and underbody sealers.

•

•

A coat of protective lacquer applied to the

whole body.

A coat of protective wax applied to the

engine bay and wheel arch areas.

The underbody wax must be reinstated following all

repairs affecting floor panels.

NOTE: Do not apply wax to engine bay of

Td5 models.

CAUTION: Old underbody wax must be

completely removed from a zone

extending at least 200 mm (7.9 in) beyond

the area where new underbody sealer is to be

applied.

In addition to the above measures, all steel parts are

zinc-coated both sides.

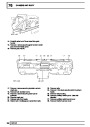

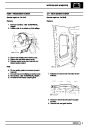

Underbody Sealer

Underfloor areas and outer sill panels are treated with

a Plastisol PVC underbody sealer. This material is not

suitable for re-treatment.

Engine Bay Wax

Reinstate protective engine bay wax disturbed during

repairs using the approved material.

When repairing areas of underbody sealer, strip the

factory-applied material back to a suitable break point,

ensuring that a clean metal surface is exposed and

that the edge of the existing material adheres soundly

to the panel.

Wheel Arch Wax

Reinstate protective wheel arch wax disturbed during

repairs using the approved material.

Blanking plugs and grommets in the floor pan (except

those used for wax injection) MUST be fitted before

underbody sealer application. Heat-fusible plugs

which have been disturbed should either be refitted

with the aid of a hot air blower or replaced with rubber

grommets.

8

SEALING AND CORROSION PROTECTION

Product Specification

| Categories | Land Rover, Land Rover Defender |

|---|---|

| Tags | Land Rover |

| Model Year | 1999, 2000, 2001, 2002 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Defender |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |