EMISSION CONTROL

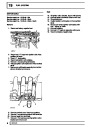

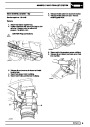

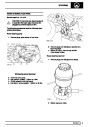

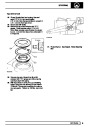

TESTING EVAPORATIVE EMISSION CONTROL -

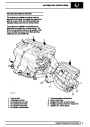

PRE ADVANCED EVAPS

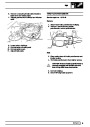

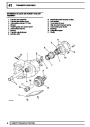

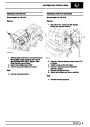

LEAK DETECTION PROCEDURE - ADVANCED

EVAPS

The following pressure test procedure is intended to

provide a method for ensuring that the system does

not leak excessively and will effectively control

evaporative emissions.

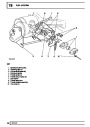

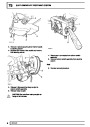

1. Connect TestBook to the vehicle and confirm

that the fault code(s) displayed relate to an

EVAP system fault.

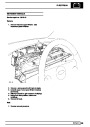

2. Examine components in fuel and EVAP system

for damage or poorly connected joints.

3. Repair or replace components to rectify any

faults found, then reset the Check Engine light

using TestBook.

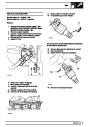

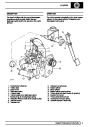

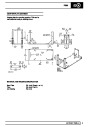

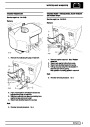

Equipment required.

Nitrogen cylinder (compressed air may be used to

pressure the system when there has NEVER been

fuel present in the fuel or evaporative control

systems).

4. Carry out Drive Cycle, See Drive Cycle -

Advanced EVAPS

5. Using TestBook confirm that the Evaporative

Loss Control (ELC) Inspection and Maintenance

(IM) flag has cleared. This procedure should

confirm that the ELC test was carried out during

the drive cycle and that the fault was cured.

Water manometer (0 - 30" H2O or more).

Pipework and a "T" piece.

Method.

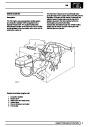

6.

If the IM flag is still shown, use TestBook to

interrogate the engine management system to

ascertain which of the following situations exists:

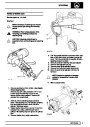

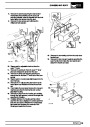

1.

Ensure that there is at least two gallons of fuel in

the petrol tank unless there has never been any

fuel in the system.

• If a fault code is shown then further investigation

is required, proceed to the next step.

2.

3.

4.

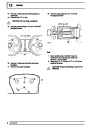

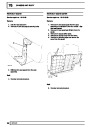

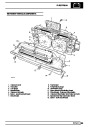

Disconnect, at the adsorption canister, the pipe

to the vapour separator.

• If the IM flag is still shown, but no faults are

indicated the conditions for the ELC check have

not been met and the drive cycle must be

repeated.

Connect this pipe to the nitrogen cylinder and

the water manometer using the "T" piece.

Pressurize the system to between 26.5 and 27.5

inches of water, allow the reading to stabilize,

then turn off the nitrogen supply.

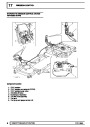

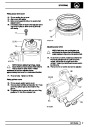

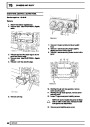

7. Connect the Leak Detection/EVAP Diagnostic

Station to the vehicle and carry out the

procedures given in the operating instructions

supplied with the equipment.

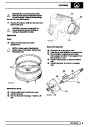

5.

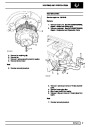

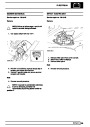

Measure the pressure drop within a period of 2

minutes 30 seconds. If the drop is greater than

2.5

inches of water the system has failed the

test. Note that a fully sealed system will show a

slight increase in pressure.

8. Rectify faults indicated by the Leak

Detection/EVAP Diagnostic Station and return to

step 4.

6.

7.

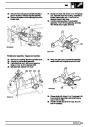

Should the system fail the test, maintain the

pressure in the system and apply a soap

solution round all the joints and connections until

bubbles appear to reveal the source of the leak.

Repeat the test and if successful, dismantle the

test equipment and reconnect the pipe to the

adsorption canister.

REV: 09/95

FAULT DIAGNOSIS

1

Product Specification

| Categories | Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1998 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |