SFI

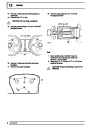

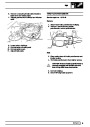

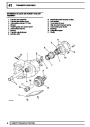

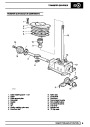

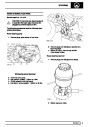

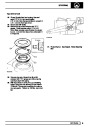

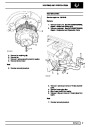

Engine fuel temperature sensor (EFT Sensor)

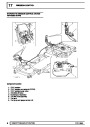

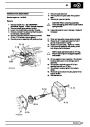

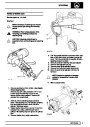

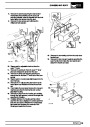

Ignition coils

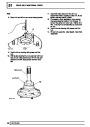

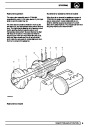

This is another resistive sensor. Located on the fuel

rail it measures temperature of the rail rather than the

fuel. The resistance varies with changes in

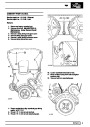

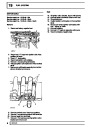

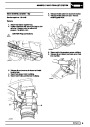

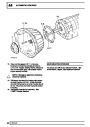

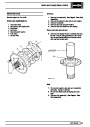

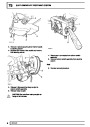

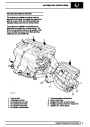

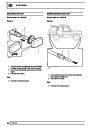

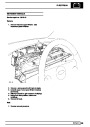

The electronic ignition system uses four double ended

coils. They are mounted on a bracket fitted to the rear

of the engine. The circuit to each coil is completed by

switching within the ECM, allowing each coil to charge

up and fire. Sparks are produced in two cylinders

simultaneously, one on compression stroke, the other

on exhaust stroke. Note that coil 1 feeds cylinders 1

and 6, coil 2 feeds cylinders 5 and 8, coil 3 feeds

cylinders 4 and 7, and coil 4 feeds cylinders 2 and 3.

Due to the ease of combustion in the cylinder on the

compression stroke, more energy is dissipated in that

cylinder. Coil failure will result in a lack of sparks and

misfire in the affected cylinders. The fault is indicated

by illumination of the malfunction indicator light (MIL)

on North American specification vehicles.

temperature. The signal is used to increase the

injection pulse time when undergoing hot restarts.

When the fuel is hot, vapourisation occurs in the rail

and bubbles can occur in the injectors. Increasing the

pulse time flushes the bubbles away, and cools the

fuel rail with fuel from the tank. The fault may not be

evident to the driver, there may be a hot restart

problem. The fault is indicated by illumination of the

malfunction indicator light (MIL) on North American

specification vehicles.

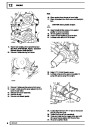

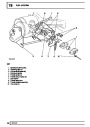

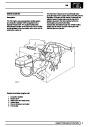

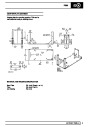

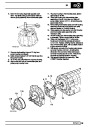

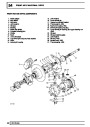

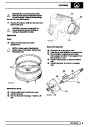

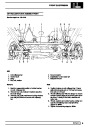

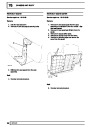

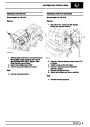

Knock sensors

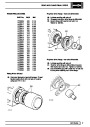

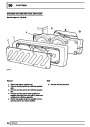

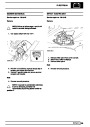

The knock sensor produces an output voltage in

proportion to mechanical vibration caused by the

engine. A sensor is located in each cylinder bank

between 2/4 and 3/5 cylinders. The ECM calculates if

the engine is knocking due to camshaft and

crankshaft sensor signals regarding the position of the

engine in the cycle. The ECM can also work out

exactly which cylinder is knocking and retards the

ignition on that particular cylinder until the knock

disappears. It then advances the ignition to find the

optimum ignition timing for that cylinder. The ECM can

adjust the timing of each cylinder for knock

simultaneously. It is possible that all eight cylinders

could have different advance angles at the same time.

If the camshaft sensor fails, the knock sensor will

continue to work, but as the engine may be running

one revolution out of sychronisation the ECM may

retard the wrong cylinder of the pair e.g. 1 instead of

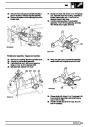

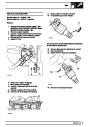

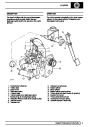

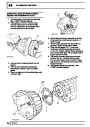

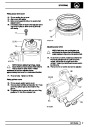

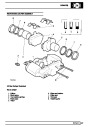

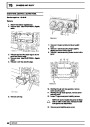

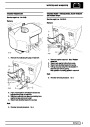

Injectors

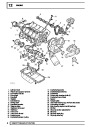

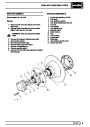

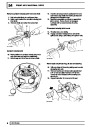

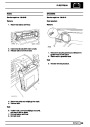

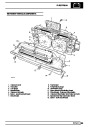

A multiport fuel injection system (MFI) is used, one

injector per cylinder. Each injector consists of a small

solenoid which is activated by the ECM to allow a

metered amount of fuel to pass into the combustion

chamber. Due to the pressure in the fuel rail and the

shape of the injector orifice, the fuel squirts into the

cylinder in a fine spray to aid combustion. In the

unlikely event of injector failure a misfire will occur as

there will be no fuel to the affected cylinder. The fault

is indicated by illumination of the malfunction indicator

light (MIL) on North American specification vehicles.

6.

If the knock sensor fails engine knock will not be

detected and corrected. The fault is indicated by

illumination of the malfunction indicator light (MIL) on

North American specification vehicles.

REV: 09/95

DESCRIPTION AND OPERATION

5

Product Specification

| Categories | Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1998 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |