19

FUEL SYSTEM

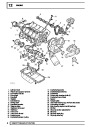

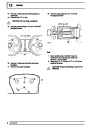

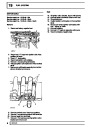

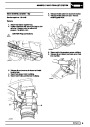

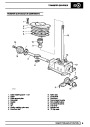

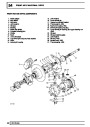

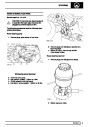

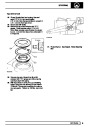

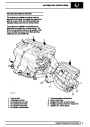

Injectors

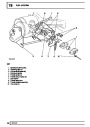

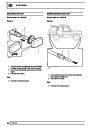

Stepper motor

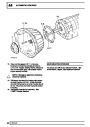

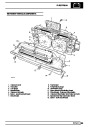

The four fuel injectors are fitted between the

pressurised fuel rail and inlet manifold. Each injector

comprises of a solenoid operated needle valve and a

specially designed nozzle to ensure good fuel

atomisation.

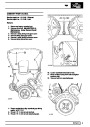

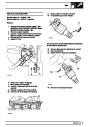

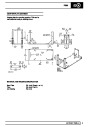

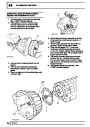

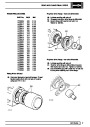

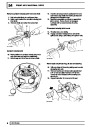

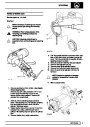

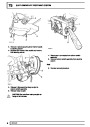

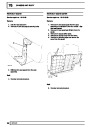

The stepper motor is contained within the throttle

housing and operates a cam and push rod via a

reduction gear. The push rod is in direct contact with

the throttle lever and moves the throttle disc to control

idle and fast idle speed. The stepper motor maximum

movement is 3.75 revolutions accomplished in steps

of 7.5°. The reduction gear converts this into 180°of

cam movement.

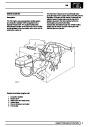

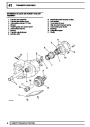

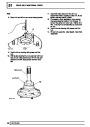

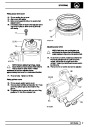

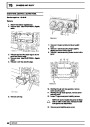

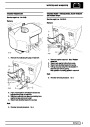

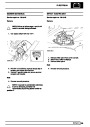

Engine coolant temperature sensor

The coolant temperature sensor is mounted in the

thermostat housing and is immersed in the engine

coolant. The sensor is a resistive device in which the

resistance varies with temperature

The throttle lever has a throttle position setting screw

which rests on the stepper motor operating pin when

the throttle pedal is released and is used to set the

relationship between engine speed and stepper motor

position.

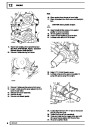

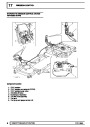

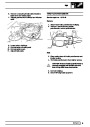

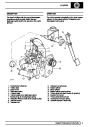

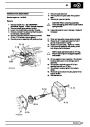

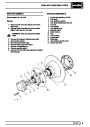

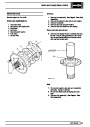

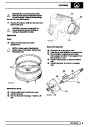

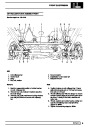

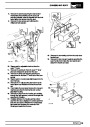

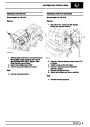

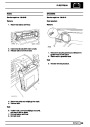

Throttle housing

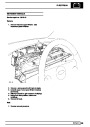

The throttle housing is attached to the inlet manifold

via a rubber sandwich plate and incorporates a throttle

disc which is connected to the throttle pedal via the

throttle lever and a cable.

In the side of the throttle housing is a throttle air

bypass bleed screw to provide easier and more

sensitive setting of the stepper motor position at idle.

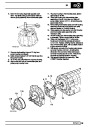

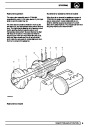

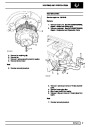

There are two breather pipes; one either side of the

throttle disc. When the engine is running with the

throttle disc open, both pipes are subject to manifold

depression and draw crankcase fumes into the

manifold. When the throttle disc is closed, only the

pipe on the inlet manifold side of the disc is subject to

manifold depression. This pipe incorporates a

restrictor to prevent engine oil being drawn into the

engine by the substantially greater manifold

depression.

The stepper motor position is checked using Testbook

and should be within the range of 20 to 40 steps when

the engine is run in. If it is identified as being outside

this range it can be adjusted to within range by turning

the throttle air bypass bleed screw. It is important to

follow Testbook setting procedure when adjusting this

screw to prevent mismatching of throttle body

settings. This ensures that the stepper motor is at the

optimum position within its range for providing further

movement to compensate for changes in engine load

or temperature in accordance with signals from the

ECM

Also incorporated in the throttle housing are the

throttle potentiometer and stepper motor.

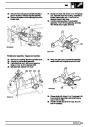

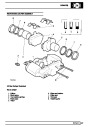

Throttle potentiometer

NOTE: The stepper motor and throttle

position setting screws must only be

adjusted when Testbook identifies the

requirement.

The throttle potentiometer is mounted in front of the

throttle housing and is directly coupled to the throttle

disc shaft.

Three wires connect the throttle potentiometer to the

ECM; a 5 volt supply to the potentiometer, an earth

return to the ECM and an output voltage to the ECM

which indicates the rate of throttle disc movement.

4

DESCRIPTION AND OPERATION

Product Specification

| Categories | Land Rover Discovery, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1995 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Discovery |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |