Mpi

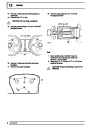

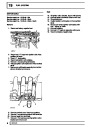

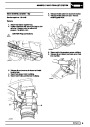

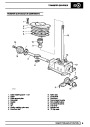

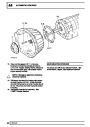

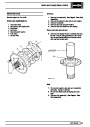

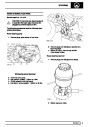

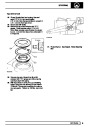

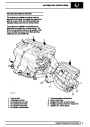

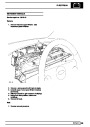

Fuel pump

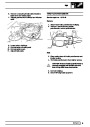

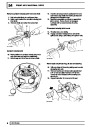

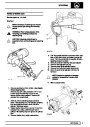

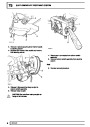

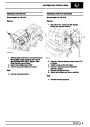

Inertia switch

The electric fuel pump, located inside the fuel tank, is

a self-priming centrifugal ’wet’ pump, the motor and

pump are filled with fuel.

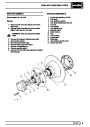

The fuel pump circuit incorporates an inertia switch

which in the event of sudden deceleration isolates the

power supply to the fuel pump. The inertia switch is

situated in the engine compartment on the bulkhead

and can, if tripped, be reset by depressing the central

plunger.

The fuel pump supplies more fuel than the maximum

load requirement for the engine, so that pressure in

the fuel system can be maintained under all

conditions.

WARNING: Check the integrity of the fuel

system before the inertia switch is reset.

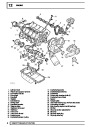

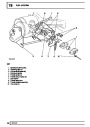

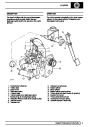

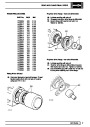

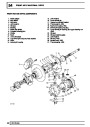

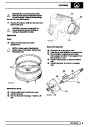

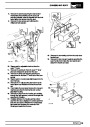

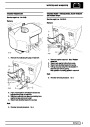

Fuel pressure regulator

The pressure regulator is a mechanical device

controlled by manifold depression and is mounted in

the fuel rail. The regulator ensures that fuel rail

pressure is maintained at a constant pressure

difference to that in the inlet manifold, as manifold

depression increases the regulated fuel pressure is

reduced in direct proportion.

Diagnostic connector

A diagnostic connector is provided to enable

diagnosis to be carried out without disturbing the

system electrical connections and to allow the ECM’s

ability to store certain faults to be utilised.

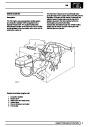

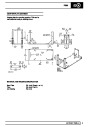

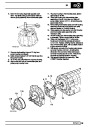

Oxygen sensor - Closed-loop emission control

The MEMS Mpi system operates a closed loop

emission system to ensure the most efficient level of

exhaust gas conversion.

When pressure exceeds the regulator setting excess

fuel is spill returned to the fuel tank swirl pot which

contains the fuel pick-up strainer.

An oxygen sensor fitted in the exhaust manifold

monitors the exhaust gases. It then supplies a small

voltage proportional to exhaust oxygen content to the

ECM As the air/fuel mixture weakens, the exhaust

oxygen content increases and so the voltage to the

ECM decreases. If the mixture becomes richer so the

oxygen content decreases and the voltage increases.

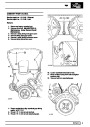

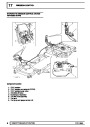

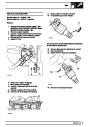

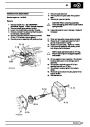

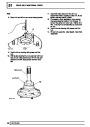

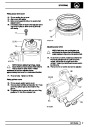

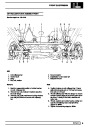

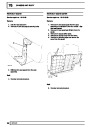

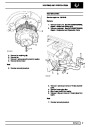

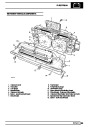

Relay module

The relay module contains the main relay, fuel pump

relay, starter relay and oxygen sensor relay and is

mounted on the ECM mounting bracket.

The main relay is energised when the ignition is

switched on and supplies current to the ECM

The ECM uses this signal voltage to determine the

air/fuel mixture being delivered to the engine, and

adjusts the injector duration to maintain the ratio

necessary for efficient gas conversion by the catalyst.

The fuel pump relay is energised by the ECM for a

short period when the ignition is switched on, during

cranking and while the engine is running.

The starter relay is energised by the cranking signal

from the ignition switch.

The oxygen sensor has an integral heating element to

ensure an efficient operating temperature is quickly

reached from cold. The electrical supply for the heater

element is controlled by the oxygen sensor relay.

This oxygen sensor relay is energised when the

ignition is switched on and supplies current to the

ECM

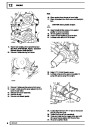

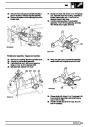

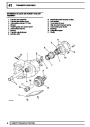

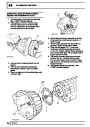

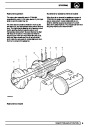

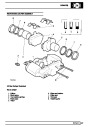

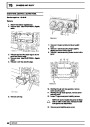

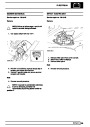

Fuel temperature sensor

The fuel temperature sensor is inserted in the fuel rail

and measures fuel and fuel rail temperatures. During

engine cranking at high temperatures, the ECM

increases fuel supply, and opens the throttle disc via

the stepper motor to aid hot starting.

Intake air temperature sensor

The intake air temperature sensor is fitted in the side

of the inlet manifold and sends the ECM a signal

relating to air temperature. The ECM uses this signal

in its calculations on air flow.

DESCRIPTION AND OPERATION

5

Product Specification

| Categories | Land Rover Discovery, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1995 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Discovery |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |