PANEL REPAIRS

Welding

5.

Apply correct sealant or adhesive, as

applicable, to panel joint surfaces.

CORROSION PREVENTION AND

1.

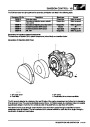

Select arms for resistance spot welding and

shape electrode tips using a tip trimmer.

+

CAUTION: Use arms not exceeding 300 mm

(11.81 in) in length.

SEALING, SEALING, Body Sealing.

Offer up and align

NOTE: To maintain weld efficiency, the tips will

require regular cleaning and dressing.

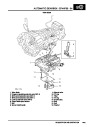

1.

Offer up new panel and align with associated

panels. Clamp into position using welding

clamps or Mole grips. Where a joggle or brace

joint is being adopted, make a set in the original

panel joint edge or insert a brace behind the

joint.

NOTE: In cases where access for welding

clamps is difficult, it may be necessary to use

tack welds.

2.

Fit resistance spot welding arms and test

equipment for satisfactory operation, using test

coupons. Where monitoring equipment is not

available, verify weld strength by checking that

metal around the weld puddle pulls apart under

tension during pulling.

77-2-18

PROCEDURES

Product Specification

| Categories | Land Rover Defender, Land Rover Discovery II, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1999 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Discovery Series II |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |