EMISSION CONTROL - V8

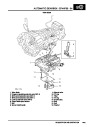

The heated oxygen sensor is screwed into threaded mountings welded into the top of the front exhaust pipes at

suitable locations. They are used to detect the level of residual oxygen in the exhaust gas to provide an instantaneous

indication of whether combustion is complete. By positioning sensors in the stream of exhaust gases from each

separate bank of the exhaust manifold, the engine management system is better able to control the fuelling

requirements on each bank independently of the other, so allowing much closer control of the air:fuel ratio and

optimising catalytic converter efficiency.

Two pre-catalytic converter heated oxygen sensors are mounted in the front pipes for monitoring the oxygen content

of the exhaust gas. NAS models also have two additional post-catalytic converter heated oxygen sensors in the

exhaust front pipe.

CAUTION: HO2 sensors are easily damaged by dropping, over torquing, excessive heat or contamination.

Care must be taken not to damage the sensor housing or tip.

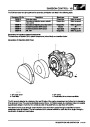

The oxygen sensors consist of a ceramic body (Galvanic cell) which is a practically pure oxygen-ion conductor made

from a mixed oxide of zirconium and yttrium. The ceramic is then coated with gas-permeable platinum, which when

heated to a sufficiently high temperature (≥ 350° C) generates a voltage which is proportional to the oxygen content

in the exhaust gas stream.

The heated oxygen sensor is protected by an outer tube with a restricted flow opening to prevent the sensor's

ceramics from being cooled by low temperature exhaust gases at start up. The post-catalytic sensors have improved

signal quality, but a slower response rate.

The pre-catalytic and post-catalytic converter sensors are not interchangeable, and although it is possible to mount

them in transposed positions, their harness connections are of different gender and colour. It is important not to

confuse the sensor signal pins; the signal pins are gold plated, whilst the heater supply pins are tinned,

mixing them up will cause contamination and adversely affect system performance.

Each of the heated oxygen sensors have a four pin connector with the following wiring details:

l

l

l

l

Sensor signal ground (grey wire – connects to engine management ECM)

Sensor signal (black wire – connects to engine management ECM)

Heater drive (white wire – connects to engine management ECM)

Heater supply (white wire – connects to fuse 2, underbonnet fuse box)

The ECM connector pins for exhaust emission control are listed in the following table:

ECM Connector 2 (C635) pin-out details for exhaust emission control system

Pin Number

2-01

Function

Post-cat sensor heater (RH) - NAS only

Post-cat sensor heater (LH) - NAS only

Post-cat sensor (RH) - NAS only

Pre-cat sensor (LH)

Signal Type

Output, Drive

Output, Drive

Ground, Signal

Ground, Signal

Ground, Signal

Ground, Signal

Output, Drive

Input, Signal

Input, Signal

Input, Signal

Input, Signal

Output, Drive

Control

PWM, 12 - 0V

PWM, 12 - 0V

0V

2-07

2-08

2-09

0V

2-10

Pre-cat sensor (RH)

0V

2-11

Post-cat sensor (LH) - NAS only

Pre-cat sensor heater (RH)

Post-cat sensor (RH) - NAS only

Pre-cat sensor (LH)

0V

2-13

PWM, 12 - 0V

Analogue, 0 - 1V

Analogue, 0 - 1V

Analogue, 0 - 1V

Analogue, 0 - 1V

PWM, 12 - 0V

2-14

2-15

2-16

Pre-cat sensor (RH)

2-17

Post-cat sensor (LH) - NAS only

Pre-cat sensor heater (LH)

2-19

The heated oxygen sensors should be treated with extreme care, since the ceramic material within them can be easily

cracked if dropped, banged or over-torqued; the sensors should be torqued to the recommended values indicated in

the repair procedures. Apply anti-seize compound to the sensor's threads when refitting.

WARNING: Some types of anti-seize compound used in service are a health hazard. Avoid skin contact.

WARNING: To prevent personal injury from a hot exhaust system, do not attempt to disconnect any

components until the exhaust system has cooled down.

CAUTION: Do not allow anti-seize compound to come into contact with tip of sensor or enter exhaust system.

NOTE: A new HO2 sensor is supplied pre-treated with anti-seize compound.

17-2-14

DESCRIPTION AND OPERATION

Product Specification

| Categories | Land Rover Defender, Land Rover Discovery II, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1999 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Discovery Series II |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |