MANIFOLDS AND EXHAUST SYSTEMS - V8

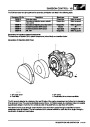

Exhaust manifolds

Two handed, cast iron exhaust manifolds are used on the V8 engine. Each manifold has four ports which merge into

one flanged outlet positioned centrally on the manifold.

Each manifold is attached to its cylinder head with eight Torx bolts. Each bolt is fitted with a 'cotton reel' shaped spacer

which allows for a longer bolt resulting in increased torque loading on each bolt. Two laminated metal gaskets seal

each manifold to its cylinder head. The flanged outlet on each manifold provides the attachment for the front pipe of

the exhaust system.

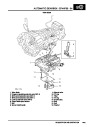

Exhaust system

The exhaust system comprises a front pipe assembly with two front pipes each incorporating a catalytic converter, an

intermediate pipe incorporating a silencer and a tail pipe assembly which also has a silencer. The exhaust system is

constructed mainly of 63 mm (2.48 in) diameter extruded pipe with a 1.5 mm (0.06 in) wall thickness. All pipes are

aluminized to resist corrosion and the silencers are fabricated from stainless steel sheet.

Front pipe assembly

The front pipe assembly is of welded and fabricated construction. A front pipe from each exhaust manifold merges

into one flanged connection. Two captive studs on the flange provide attachment to the intermediate pipe with

locknuts. Each front pipe has a welded flange which is attached to each manifold and secured with three studs and

flanged nuts and sealed with a metal laminated gasket. The gasket comprises a heat resistant fibre between two thin

metallic layers to enhance the sealing properties of the gasket.

A catalytic converter is located in each front pipe. The catalytic converters are different shapes to allow clearance

between the body and transmission. Both catalytic converters are of similar internal construction.

+

EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Emission Control Systems.

CAUTION: Ensure the exhaust system is free from leaks. Exhaust gas leaks upstream of the catalytic

converter could cause internal damage to the catalytic converter.

From the catalytic converters, the front pipes merge into one pipe which terminates at a flanged joint. The flange

connects with the intermediate pipe, sealed with an olive and secured with studs and locknuts.

Intermediate pipe and silencer

The intermediate pipe is of welded and fabricated tubular construction. It connects at its forward end with a flange on

the front pipe assembly and is secured with locknuts to captive studs in the front pipe assembly flange. The rear

section of the intermediate pipe connects to the tail pipe assembly via a flanged joint, sealed with a metal gasket and

secured with locknuts and studs.

The forward and rear sections are joined by a silencer. The silencer is fabricated from stainless steel sheet to form

the body of the silencer. An end plate closes each end of the silencer and is attached to the body with seam joints.

Perforated baffle tubes inside the silencer are connected to the inlet and outlet pipes on each end plate. Internal baffle

plates support the baffle tubes and together with a stainless steel fibre absorb combustion noise as the exhaust gases

pass through the silencer.

The intermediate pipe is attached by two brackets, positioned at each end of the silencer, and mounting rubbers to

the chassis. The mounting rubbers allow ease of alignment and vibration absorption. The two mounting rubbers are

fitted with removable heat deflectors to prevent heat from the silencer damaging the material.

Tail pipe assembly

The tail pipe is of welded and fabricated construction. It connects to the intermediate pipe with a flanged joint secured

with studs and locknuts and sealed with a metal gasket. The pipe is shaped to locate above the rear axle allowing

clearance for axle articulation. The pipe is also curved to clear the left hand side of the fuel tank which has a reflective

shield to protect the tank from heat generated from the pipe.

A fabricated silencer is located at the rear of the tail pipe. The silencer is circular in section and is constructed from

stainless steel sheet. A baffle tube is located inside the silencer and the space around the baffle tube is packed with

a stainless steel fibre. The holes in the baffle tube allow the packing to further reduce combustion noise from the

engine. The tail pipe from the silencer is curved downwards at the rear of the vehicle and directs exhaust gases

towards the ground. The curved pipe allows the exhaust gases to be dissipated by the airflow under the vehicle and

prevents gases being drawn behind the vehicle.

The tail pipe is attached by a bracket, positioned forward of the silencer, and a mounting rubber to the chassis. The

mounting rubber allows ease of alignment and vibration absorption.

30-2-6

DESCRIPTION AND OPERATION

Product Specification

| Categories | Land Rover Defender, Land Rover Discovery II, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1999 |

| Download File |

|

| Document Type | Workshop Manual |

| Language | English |

| Product Name | Discovery Series II |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |