68

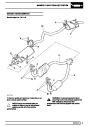

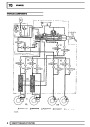

AIR SUSPENSION

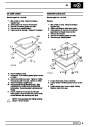

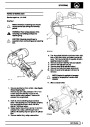

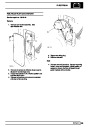

DISCONNECT/CONNECT AIR PIPE

Remove

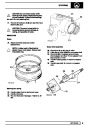

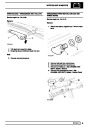

NOTE: Air pipe may be trimmed if

sufficient straight pipe remains. Ensure

pipe end is cut square, without distortion

or frays to obtain air tight seal. Use service tool

LRT-60-002. Lightly chamfer pipe using a pencil

sharpener after cutting. DO NOT CUT PIPES

MORE THAN TWICE.

WARNING: Air suspension is pressurised

up to 10 bar. Dirt or grease must not enter

the system. Wear hand, ear and eye safety

standard protection when servicing system.

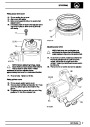

Refit

1.

2.

Depressurise complete system. See

Adjustment, Depressurise System

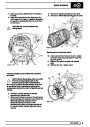

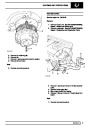

6. Push pipe firmly through two ’O’ rings until it

contacts base of housing as shown. Gently pull

pipe to ensure connection. The collet will retain

some movement while depressurised. Refit

rubber boot.

CAUTION: Air pipes may be damaged if

not disconnected correctly, resulting in

possible leaks.

7.

Pressurise system. See Adjustment,

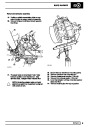

Clean air pipe connection with stiff brush and

soapy water. Peel back rubber boot.

Depressurise System

8. Leak test connection. See Adjustment, Leak

Test Procedure

3.

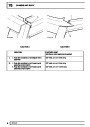

Apply equal downward pressure on collet flange

at ’A’ as shown.

4.

5.

Pull air pipe firmly out through centre of collet.

Inspect disconnected end of air pipe for damage

and scores. Rectify as necessary.

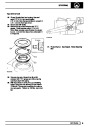

2

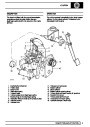

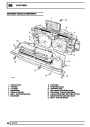

REPAIR

Product Specification

| Categories | Land Rover, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1995 |

| Download File |

|

| Document Type | Owners Manual |

| Language | English |

| Product Name | Range Rover Classic |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |