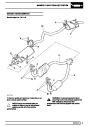

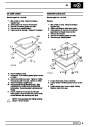

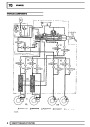

WIPERS AND WASHERS

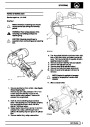

WIPER MOTOR CHECKING

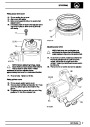

NOTE: These instructions apply to

NOTE: If vehicle wiring connections are

disconnected and an alternative supply

source is applied it is essential that

Windscreen and Tailgate wiper motors.

correct polarity is observed. Failure to observe

this will cause motor to rotate in reverse direction,

which may result in limit switch contacts being

damaged.

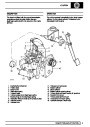

If unsatisfactory operation of wiping equipment is

experienced, a systematic check to determine fault

should be carried out:

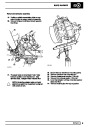

3.

If motor does not run satisfactorily or takes

higher than normal current, a fault exists and

must be remedied.

1.

Check blades for signs of excessive friction. This

reduces wiping speed of motor and cause

increased current draw which may damage

armature. Check by substitution.

4. If current consumption and speed of motor are

satisfactory. A check should be carried out for

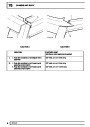

proper functioning of transmission linkage and

wiper arm shafts.

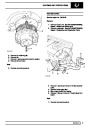

2.

Check windscreen wiper motor light running

current and speed with motor coupling link

disconnected from wiper shaft transmission

linkage.

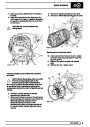

NOTE: Service parts are not available for

windscreen and tailgate wiper motors with

exception of windscreen wiper rotary

connecting link.

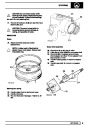

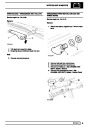

Check tailgate glass wiper motor with wiper connected

and glass wet. Connect an ammeter in series with

motor supply. Measure current consumption when

motor is switched on. Check operating speed by

timing speed of rotation of motor coupling link. The

results should compare with figures given in ’General

Specification Data’.

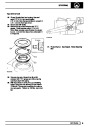

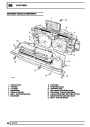

FAULT DIAGNOSIS

1

Product Specification

| Categories | Land Rover, Range Rover |

|---|---|

| Tags | Land Rover |

| Model Year | 1995 |

| Download File |

|

| Document Type | Owners Manual |

| Language | English |

| Product Name | Range Rover Classic |

| Product Brand | Land Rover |

| Document File Type | |

| Publisher | landrover.com |

| Wikipedia's Page | http://en.wikipedia.org/wiki/Land_Rover |

| Copyright | Attribution Non-commercial |